What Materials Are Used for Trenchless Sewer Relining?

Used for Trenchless Sewer Relining

Trenchless sewer relining uses newer, better quality pipes that are much less likely to crack, break or be invaded by tree roots than older pipe materials. These pipes are also designed to be long-lasting, and can last up to 50 years or more. The relining process itself can be completed in just days, and the results are a pipe that is free of cracks, leaks and corrosion.

The cost of trenchless sewer relining is typically lower than the traditional method because it doesn’t involve tearing up your landscaping, sidewalks and other parts of your property. However, the cost can vary depending on the condition of the pipes and whether it’s necessary to dig up any parts of your home or other structures. You should always get an estimate before hiring someone for this work.

Angi can help you find local plumbers who are experienced in trenchless sewer relining and other services. These professionals will be able to give you an accurate idea of what the cost will be and how long it will take to complete the work.

What Materials Are Used for Trenchless Sewer Relining?

One of the biggest factors that influences the cost of trenchless sewer relining is the condition of the pipes themselves. If your pipes are old and brittle, or they’re back pitched (meaning the wastewater is flowing toward your home instead of away from it), the repairs will be more expensive. Additionally, if the pipes are very long or have a lot of bends and elbows, the costs will be higher because those areas are more difficult to access with traditional digging techniques.

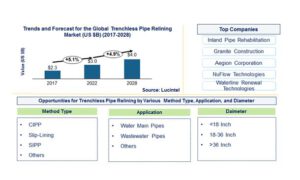

The type of relining material used will also affect the cost. Some methods, such as CIPP lining, use a soft epoxy liner that is inserted into the old pipe and inflated to create a new, undamaged interior surface within your existing pipe. This is the best option for pipes that are cracked or leaky and is highly recommended by governing bodies because it prevents water leakage into your yard, garden and other outdoor spaces.

Slip lining and spray lining are other trenchless repair options. These methods are great for halting or eliminating corrosive issues in your cast iron pipes or getting rid of sewer gas that’s coming from leaky joints. However, these methods aren’t suitable for all types of pipes, and the liner will not be able to make it around sharp bends without wrinkling.

For large jobs, a pull-in-place lining method may be needed. This involves winching a sleeve into your pipe, and can restore nearly any pipe as long as it’s accessible from both ends. The other method, inversion lining, requires an air compressor to blow the sleeve into place from inside out, and can fix even the most damaged pipes quickly. If you decide to go with either of these methods, be sure to select high-quality RSM liner and resin from your supplier. These are Australian watermarked approved and meet AS/NZ3500 regulations. They’re also 5 times stronger than PVC, which means that they can resist cracking and bursting.